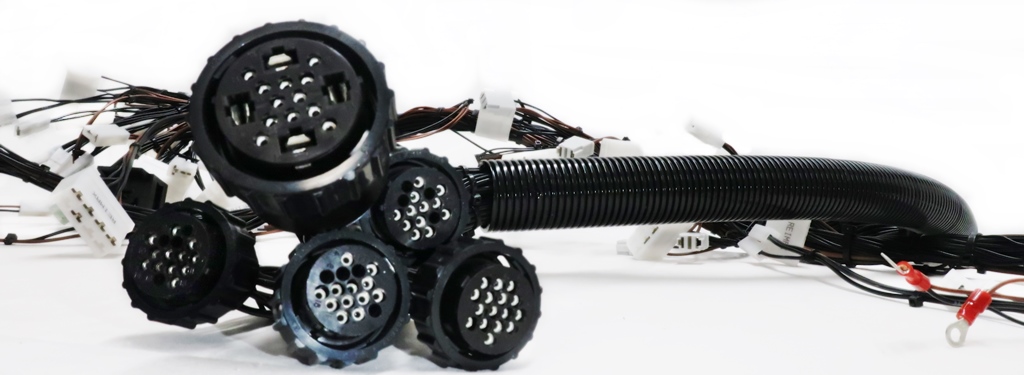

Harnesses, spirals and cables

We manufacture custom-made individual wires and larger wire harnesses. Our wire harness production is UL and CSA -approved and it is also possible to add the FI NSC marking to the equipment cables. We ensure the quality of our products with continuous training, and our personnell is trained according to the IPC620.

Our harness production is flexible and modern. The automatic lead maker equipment featuring marking devices allows for automatic production of harnesses in the 0.09–6.00 mm² range. Our semi-automatic machines allows connecting wires with diameters of up to 240 mm². Our automatic production is also supported by various types of presses as well as cutting and stripping machines. All harness series produced by us are pre-tested electrically at the production stage.

EXAMPLE APPLICATIONS OF WIRING HARNESSES

- Piling machines

- Trams and trains

- Agricultural and forestry machines

- Cranes and excavators

- Trucks

- Boats

- Masts and base stations

Equipment cables

We also manufacture equipment cables and we are able to process cables up to 50mm outer diameter. We process cables from different materials and cable doesn't need to be round. Our machinery enables the processing of even thin AWG40 as well as rigid and radiating coaxial cables. We master all connection techniques such as soldering, compression connections, insulation-displacement contacts and ultrasonic welding.

We also manufacture equipment cables and we are able to process cables up to 50mm outer diameter. We process cables from different materials and cable doesn't need to be round. Our machinery enables the processing of even thin AWG40 as well as rigid and radiating coaxial cables. We master all connection techniques such as soldering, compression connections, insulation-displacement contacts and ultrasonic welding.

We are able to also make connector end parts, strain reliefs and splitters for equipment cables using injection molding.

When manufacturing equipment cables, the customer's needs are always taken into account. A heat- or oil resistant cable is often chosen to meet the requirements of the operating conditions.

Spiral cables

Spiral cable is especially suitable solution for moving machines and equipment’s since 1 meter of spiral cable contains up to 5 to 7 meters of uncoiled cable. Spiral cable does not get stuck and is therefore more user-friendly and increases safety.

Spiral cable is especially suitable solution for moving machines and equipment’s since 1 meter of spiral cable contains up to 5 to 7 meters of uncoiled cable. Spiral cable does not get stuck and is therefore more user-friendly and increases safety.

We produce spiral cables for required diameters and lengths. The used material of outer jacket is either PUR or special PVC. Also equipment cables such as M12 sensor cable can be used in spiral cables.

The cable choice is affected by the working conditions of the end product. Robust PUR is equipped with high recoiling forces and high resistance to extreme temperatures and conditions as well as to oil and chemicals. PUR cables have a wide temperature range for applications in harsh climatic environments, depending on cable, from +90°C to -50°C. In addition PUR-cable has a good resistance of the outer sheath to cutting and abrasion and is suitable for indoor and outdoor use.

Special PVC is cost efficient solution for indoor use with the convenience and safety of spiral cable.

Spiral cable is perfect choice for example in construction industry and medical equipment’s as well as in shipyards and freight handling. Spirals can be used for example in factories and facilities, in-store cooling equipment’s, powered doors and charging cables.